Marble countertops occupy a rare position in kitchen design: they are both a high‑performance building material and a powerful aesthetic statement that signals craftsmanship, luxury, and permanence. For architects, designers, contractors, and homeowners working at the premium end of the market, understanding exactly how marble behaves—as a geological material and as a work surface—is essential before specifying it in a kitchen.

For Future Stone Group, marble countertops sit alongside marble dining tables, coffee tables, wall panels, and engineered stone surfaces as part of an integrated stone palette for villas, hotels, and high‑end residences. This guide is designed to help you decide when natural marble is the right choice for a kitchen, when a hybrid specification might be smarter, and how to detail and maintain the stone so it performs as beautifully as it looks.

What Marble Countertops Really Are

Marble is a metamorphic stone formed when limestone is subjected to heat and pressure, reorganizing its calcite crystals and creating the flowing veining patterns that distinguish materials such as Carrara, Calacatta, Arabescato, and Calacatta Viola. This mineral composition gives marble its characteristic softness under the hand, its ability to take a high polish, and its sensitivity to acids compared with silicate stones like granite and quartzite.

In countertop applications, marble is typically fabricated in $2 cm or $3 cm thicknesses, either as solid slabs or with mitered build‑ups at island edges to create the impression of greater mass. Slabs are cut, reinforced at sink and cooktop openings, and installed according to industry standards such as the Natural Stone Institute’s Dimension Stone Design Manual, which governs issues like substrate preparation, overhang limits, joint width, and tolerances.

Because every marble block is unique, no two slabs are identical, which allows designers to treat the countertop not just as a surface but as a large‑scale piece of natural artwork that can be book‑matched, vein‑matched, or contrasted between island and perimeter runs. Future Stone Group curates a range that spans quiet grey‑veined whites through to expressive stones such as Calacatta Viola and dramatic Black Marquina, enabling different levels of visual intensity within the same project.

Performance in a Working Kitchen

From a structural standpoint, marble countertops are robust and long‑lasting when correctly supported and installed, which is why natural stone remains a mainstay of premium residential and hospitality kitchens. Where marble differs from quartz and granite is in surface durability: it is softer, more porous, and chemically reactive with acids, which means it will show wear, patina, and occasional damage under heavy use.

Daily use introduces three main stressors: mechanical abrasion (scratching and impact), staining (liquid absorption), and etching (acid attack on the calcite matrix). Sliding plates, pots, and metal objects can leave fine scratches; dropped pans or heavy equipment can chip edges; and frequent contact with wine, citrus, vinegar, and tomato sauce will etch polished surfaces, dulling the gloss in localized spots even when the stone is properly sealed.

Heat performance is generally very good for natural marble: it does not scorch or melt and is more tolerant of hot pots than many resins or laminates, though abrupt thermal shock can still crack thin projections or unreinforced overhangs. For high‑end projects where cooking is serious and daily, the stone’s strengths are best leveraged by careful zoning—placing marble in areas optimized for plating, baking, and socializing, and combining it with harder or less reactive materials at the most punishing cooktop and sink stations.

Aesthetic Potential and Design Language

The primary reason marble remains a specification staple in luxury markets is its visual depth and the way it interacts with light. Fine crystals within the stone create a soft, almost translucent quality that synthetic surfaces still struggle to replicate, especially in large islands and long runs where veining can flow continuously.

Color and pattern options are broad, but they can be grouped architecturally: quiet whites and greys (Carrara, Arabescato, many Danby stones), bold high‑contrast whites (classic Calacatta families), richly veined violets and wines (Calacatta Viola), and deep charcoals and blacks with white veining (Black Marquina and similar stones). Current design trends in 2024–2025 favor pronounced, almost graphic veining on islands—often book‑matched—paired with more restrained surfaces on the perimeter to keep sightlines calm.

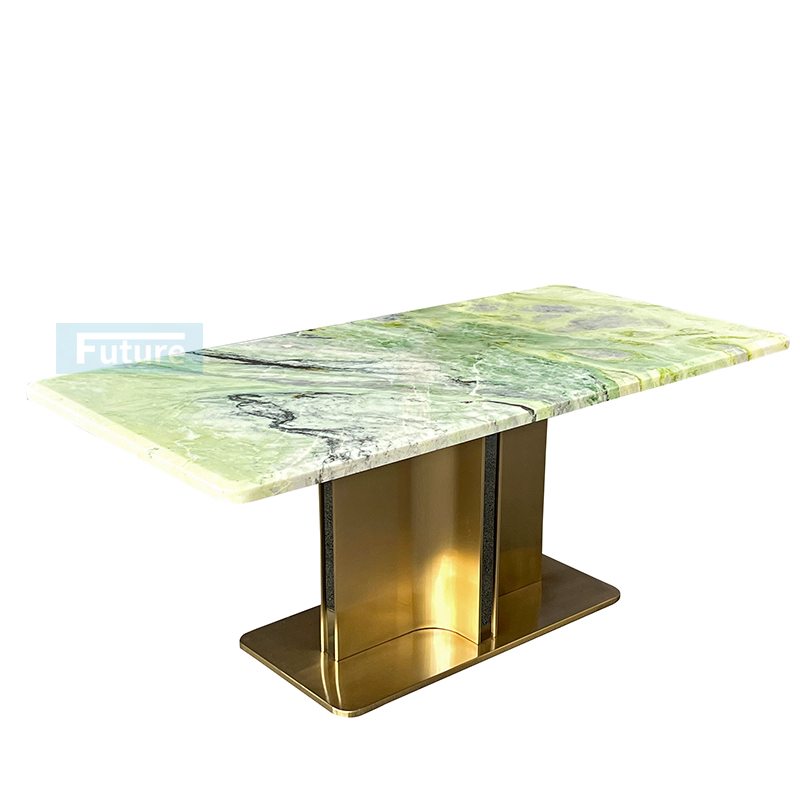

Marble also works powerfully in composition with other elements: natural timber, brushed metals, fluted joinery, and large‑format stone or porcelain floor tiles can be tuned to either emphasize the stone’s drama or let it recede into a quietly luxurious backdrop. Future Stone Group’s portfolio extends beyond countertops to coordinated marble floors, wall panels, staircases, console tables, and marble dining and coffee tables, allowing a single stone story to flow seamlessly from kitchen into living and dining spaces.

Finish Choices: Honed, Polished, and Beyond

Finish selection is one of the most consequential decisions for both performance and appearance. Polished marble is highly reflective, intensifying color and veining while offering slightly improved resistance to liquid penetration because the surface topography is smoother at a microscopic level. However, that same gloss makes etch marks and hairline scratches much more visible, since any dull patch reads immediately against the surrounding shine.

Honed marble has a matte or satin sheen that many architects now favor for contemporary luxury kitchens, particularly in Europe, North America, and Australia. The honed surface tends to disguise etches and fine scratches because the overall reflectance is lower and more uniform, though the slight increase in surface openness can make honed finishes marginally more stain‑prone without diligent sealing.

More specialized textures—such as leathered, brushed, or antiqued finishes—can add tactile richness and grip, and they often conceal wear even more effectively, though they change how the stone reflects light and may be better suited to islands, bar tops, or auxiliary surfaces than to every linear meter of worktop. Future Stone Group routinely fabricates countertops and matching marble coffee and dining tables in mixed finishes, using polished surfaces where maximum visual drama is desired and honed or textured finishes where touch, grip, and forgiving maintenance are the priority.

Technical Design Considerations for Professionals

Well‑detailed marble is as much an engineering exercise as an aesthetic one, especially in large kitchens and open‑plan spaces. Industry guidance such as the Natural Stone Institute’s Dimension Stone Design Manual sets out best practices for substrate flatness, support spacing, joint placement, and reinforcement around sink and hob cut‑outs, all of which should be followed to ensure long‑term performance.

For overhangs, typical design limits (always verify for each project) are approximately $152 mm ($6 in) for $20 mm ($2 cm) countertops and around $254 mm ($10 in) for $30 mm ($3 cm) tops, beyond which concealed steel or other structural support is generally required. Rodding—embedding reinforcing bars in grooves beneath the stone at vulnerable areas like sink fronts—remains a common technique in high‑traffic kitchens and is especially recommended for heavily veined marbles where the veining orientation could otherwise create natural lines of weakness.

Joint location, seam width, and color‑matched epoxy work are critical to preserving the visual continuity of veined marbles, particularly Calacatta‑type stones and Calacatta Viola where pattern flow is a major part of the design concept. Future Stone Group’s fabrication teams routinely vein‑match and book‑match large islands, backsplash returns, and even downstands on marble tables and stone islands, ensuring that architectural lines and veining directions read as one coherent composition.

Maintenance and Lifecycle Planning

Marble is not a “fit and forget” surface, and successful projects treat care as part of the design brief from day one. Penetrating sealers are the first line of defense against staining; most stone specialists recommend resealing kitchen marble every $6–$12 months depending on usage, color, and the specific sealer chemistry. High‑traffic family kitchens or light, absorbent marbles benefit from shorter cycles, whereas darker or denser stones in lower‑use holiday homes may extend toward the upper end of that range.

For day‑to‑day cleaning, pH‑neutral stone cleaners or mild dish soap in warm water are preferred, while vinegar, citrus‑based cleaners, bleach, and abrasive powders should be avoided because they can accelerate etching and degrade sealers. Cutting boards, coasters, and trivets are still recommended over any natural stone, not because marble is fragile, but because mechanical and chemical abuse accumulate over time and are much harder to reverse once widespread.

Unlike many synthetic materials, natural marble can be professionally re‑honed and repolished after years of use, often restoring a tired surface to near‑new condition without replacing the slabs. For long‑horizon projects—luxury villas, signature residences, or prestige hospitality properties—this ability to plan periodic restoration into the lifecycle cost is one reason marble remains attractive despite its higher day‑to‑day maintenance needs.

Cost, Budgeting, and Value in 2025

In 2025, marble sits comfortably in the mid‑to‑premium band of countertop costs, overlapping with higher‑grade granites and engineered stones. Across North American projects, installed pricing for kitchen marble typically ranges from around $80–$250 USD per square foot, depending on stone selection, thickness, edge complexity, and local labor rates.

Material‑only costs for more common marbles such as Carrara often fall in the $40–$100 USD per square foot range, whereas rarer or more in‑demand marbles like many Calacatta variants can command well over $150 USD per square foot and, in some cases, approach or exceed $200 USD per square foot. Recent analyses also note that tariffs and logistics have pushed imported marble pricing up by roughly $20 in some regions, so architects and clients should always work from current local quotations when preparing budgets.

For a typical residential kitchen, these figures translate into project totals of roughly $2,000–$5,000 USD, with compact layouts occasionally coming in closer to $600–$1,500 USD and expansive, high‑specification luxury kitchens—especially with large islands in premium stones—easily reaching five‑figure sums. When marble is part of a holistic stone package including flooring, wall cladding, staircases, and marble dining or coffee tables, Future Stone Group’s integrated supply can also create economies of scale in procurement and logistics compared with piecemeal sourcing.

Marble, Quartz, and Granite: A Technical Comparison

For many clients, the real question is not “Is marble good?” but “Is marble better than quartz or granite for this project and this lifestyle?”. The answer depends on priorities: appearance, maintenance tolerance, mechanical performance, and budget.

| Aspect | Marble | Quartz (engineered) | Granite |

|---|---|---|---|

| Composition | Natural calcite‑based stone with veining. | Engineered slab of quartz aggregate and resin. | Natural igneous stone rich in quartz and feldspar. |

| Stain resistance | Porous and stain‑prone without regular sealing. | Non‑porous and highly stain‑resistant. | Lower absorption than marble once sealed. |

| Etch resistance | Chemically reactive with acids and easily etched. | Generally resistant to household acids. | Largely unaffected by typical kitchen acids. |

| Scratch resistance | Softer, so more prone to scratching and edge chipping. | Hard and very scratch‑resistant. | Very scratch‑resistant under normal use. |

| Heat performance | Good, but avoid thermal shock and direct hot pans on thin edges. | Sensitive to high heat because of resins. | Excellent heat resistance for daily use. |

| Maintenance | Requires sealing, gentle cleaners, and acceptance of patina. | Minimal maintenance and no sealing needed. | Requires periodic sealing but otherwise robust. |

| Aesthetic | Unique veining and soft light; classic luxury material. | Highly consistent; marble‑look options available. | Varied movement and color; more granular patterns. |

For clients who insist on the drama of Calacatta‑style veining but cannot accept etching or frequent sealing, high‑quality marble‑look quartz or sintered stone may be the most appropriate solution in the core work zones. Many Future Stone Group projects therefore combine natural marble islands or feature walls with engineered quartz or sintered stone countertops at the hob and sink, balancing emotional impact with day‑to‑day practicality.

Project Scenarios: When Marble Is and Is Not the Right Choice

For architect‑designed homes and luxury villas, marble is often the correct answer when the kitchen is conceived as a showpiece that opens onto living and dining areas. In these projects, the client typically accepts the idea of patina, and the kitchen may include dedicated marble zones for plating, casual dining, or entertaining, while the most intensive prep happens on secondary surfaces.

In hospitality, boutique hotels, and serviced apartments, marble islands, bars, and reception counters continue to deliver exceptional visual return, especially when paired with coordinated bathroom vanities, tabletops, and lobby flooring in the same stone. Many operators understand that periodic professional restoration is part of the operating cost, just as with timber floors or fine upholstery, and value the way marble supports a premium room rate and brand story.

By contrast, in high‑traffic family kitchens with young children, constant snacking, and frequent entertaining, marble can be more challenging unless everyone in the household is comfortable with visible wear. In those scenarios, designers often specify marble more selectively—as a baking station, a raised bar, or a dramatic backsplash—and rely on engineered quartz or robust granites for the main working countertops.

How Future Stone Group Supports Your Specification

Future Stone Group operates not only as a supplier of slabs but as a full‑scope stone partner, from block selection through fabrication of countertops, furniture, and architectural stonework. The product portfolio spans natural marble slabs and tiles, marble kitchen countertops, marble dining and coffee tables, onyx and travertine, granite and quartz alternatives, and engineered marble and quartz surfaces for value‑engineered or high‑performance applications.

For architects and designers working in high‑end markets, the ability to source coordinated marble floors, stairs, wall panels, wash basins, side tables, and kitchen worktops from a single manufacturer simplifies detailing, color matching, and logistics. For developers and contractors in fast‑growing emerging markets, Future Stone Group’s mix of premium marbles and cost‑effective engineered stone solutions enables calibrated specifications that align with project budgets while preserving a luxury visual language.

Technical teams can advise on slab selection, reinforcement strategies, edge profiles, overhangs, and joint layouts in line with international best practice and Natural Stone Institute guidelines, ensuring that marble countertops are beautiful on day one and engineered for decades of service. Whether the brief calls for a sculptural Calacatta Viola island, a run of quietly elegant Carrara countertops, or a full ensemble of marble tables and stone elements throughout a villa or hotel, Future Stone Group is positioned to support the design vision from concept through completion.